Lithium extraction in the Altmark

Lithium is an essential raw material for the production of lithium-ion batteries, for example in electromobility, and is therefore a central component of the energy transition. Domestic lithium production to supply of critical raw materials is being enabled in the Altmark region of Saxony-Anhalt.

In April 2024, the Saxony-Anhalt Mining Authority granted Neptune Energy approval to extract lithium in the Altmark region. The licence relates to an area that is largely congruent with the already developed Altmark natural gas field. In August 2025, we commissioned the internationally renowned and independent assessment company Sproule ERCE to determine the resource base for the project (CIM / NI43-101 standard). As a result, the experts defined resources of 43 million tonnes of lithium carbonate equivalent (LCE) in the Altmark. This means that northern Saxony-Anhalt is home to one of the largest project-related lithium resources in the world.

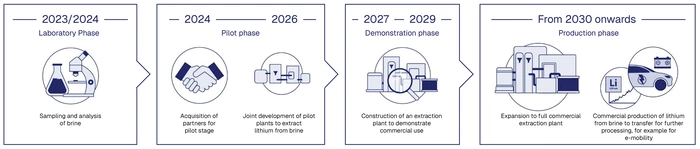

Decades of experience in natural gas production are now forming the basis for the energy supply of tomorrow: various technologies for extracting lithium from brine will be tested as part of a pilot phase until mid-2026. The aim is to gain reliable insights for further project development and potential commercial production. This will be followed by a demonstration phase in which the use of an extraction plant will be trialled as the next step towards commercial production.

Security of supply with critical raw materials

The Altmark combines geological potential, established infrastructure and technical expertise — ideal conditions to reduce Germany’s dependence on raw material imports. According to current calculations, the potential resource in the Altmark is around 43 million tonnes of lithium carbonate. The first evidence of lithium deposits dates back to geological surveys as part of natural gas extraction in the 1970s. The first lithium extraction plant was about to be commissioned in 1989.

If scaled up commercially, up to 25,000 tonnes of lithium carbonate could be produced annually - enough to supply around 500,000 electric cars per year with battery material and make Germany less dependent on imports of raw materials. Our project contributes directly to the goals of the German government's raw materials strategy, which calls for a strengthening of domestic raw materials security and extraction.

Various currently available technologies will be tested in pilot phases until mid-2026 in order to gain important insights for further project development and possible commercial production.

This began in November 2024 with a pilot plant from the French company Geolith. Neptune Energy supplied brine from existing natural gas wells and the lithium dissolved in the water was extracted in small quantities using an ion exchange process. The intermediate product lithium chloride was then converted into lithium carbonate with a purity of 99.9% in the company's own laboratory in Steinitz as well as by experts from Kellogg Brown & Root GmbH (KBR) in Bad Homburg and further refined.

The second pilot trial with Californian provider Lilac Solution ran from June to August 2025. Their mobile containerised plant processed the brine directly on site in the Altmark. The resulting lithium chloride was concentrated by Lilac Solutions in a field laboratory in Steinitz, treated and converted into battery-grade lithium carbonate in a plant.

From mid-September until mid-October, we tested an adsorption process in the third pilot project. As part of an adsorption process, the brine passes passed through a special aluminium hydroxide sorbent, which selectively attracts the lithium salt (LiCl) present. When the sorbent is loaded, the bound lithium salt is released from the adsorber by rinsing with demineralised water. When the sorbent is loaded, the bound lithium salt is released from the adsorber by rinsing with demineralised water.

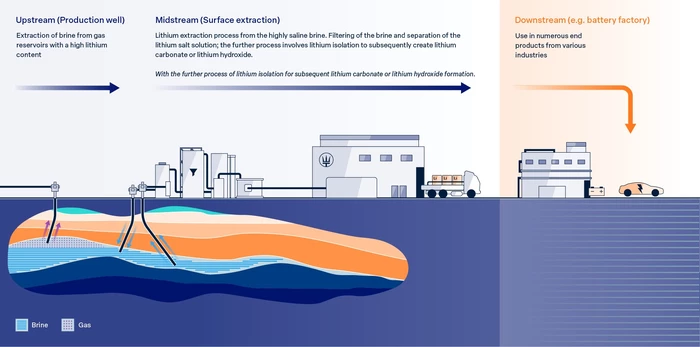

In the Altmark, we rely on the environmentally friendly process of direct lithium extraction (DLE) from brine. In this process, brine is channelled from the depths to the surface, treated in processing plants and then the lithium is isolated using a DLE process. Any remaining water is pumped back into the reservoir. The sustainable reutilisation of the existing natural gas infrastructure in the Altmark minimises the impact on the environment. We completely avoid open-cast mining and large evaporation ponds - as they are known from Australia, Chile or China.

The DLE process utilises filter materials that are used during extraction. There are different approaches to lithium ion filtration. Neptune is testing ion exchangers, membrane technologies and adsorption media.

Our licence area in the Altmark

Neptune Energy has held the "Jeetze - L" mining licence for the extraction of lithium in the Altmark since April 2024. The authorised area largely coincides with the Altmark natural gas field that has already been developed. We are authorised to produce lithium within this area, provided that all further steps are approved by the responsible Saxony-Anhalt Mining Authority (LAGB). In addition to the mining licence, Neptune Energy holds three exploration licences. "Milde A-L" and "Milde C-L" were already awarded to the company in 2024, followed by the "Milde B-L" licence in the south-eastern part of the Altmark in 2025.

Transparency and dialogue for lithium from Saxony-Anhalt

An open, continuous dialogue with relevant stakeholders is a central component of the project development of the Altmark Lithium Project. We want to enable domestic lithium production in Saxony-Anhalt - responsibly, efficiently and in dialogue with the region. Our aim is to create sustainable added value for the region, the economy and society.

The focus is on regular dialogue with municipalities, authorities, land users and representatives from business, science and civil society. We want to identify opportunities and potential at an early stage. As the project is currently in an early phase, we are focussing on clear information and reliable communication - as a basis for the next project steps.